Sensor

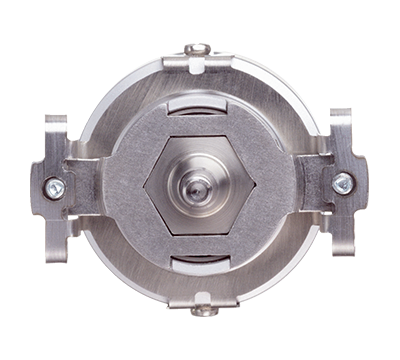

Motor Feedback Systems Rotary HIPERFACE SICK SKS/SKM36

Type:SKM36-HFA0-K02

Part No.:1034094

Part No.:1034094

Motor Feedback Systems Rotary HIPERFACE SICK SKS/SKM36 SKM36-HFA0-K02

Performance

Interfaces

Electrical data

Mechanical data

Ambient data

Classifications

Performance

| Sine/cosine periods per revolution | 128 |

| Number of the absolute ascertainable revolutions | 4,096 |

| Total number of steps | 16,777,216 |

| Measuring step | 2.5 ″ For interpolation of the sine/cosine signals with, e. g., 12 bits |

| Integral non-linearity | ± 80 ″, Error limits for evaluating sine/cosine period |

| Differential non-linearity | ± 40 ″, Non-linearity within a sine/cosine period |

| Operating speed | ≤ 9,000 min⁻¹, up to which the absolute position can be reliably produced |

| Available memory area | 1,792 Byte |

| System accuracy | ± 120 ″ |

Interfaces

| Type of code for the absolute value | Binary |

| Code sequence | Increasing, when turning the shaft For clockwise rotation, looking in direction “A” (see dimensional drawing), For clockwise shaft rotation, looking in direction “A” (see dimensional drawing) |

| Communication interface | HIPERFACE® |

Electrical data

| Connection type | Male connector, 8-pin, radial |

| Supply voltage | 7 V DC ... 12 V DC |

| Recommended supply voltage | 8 V DC |

| Power consumption | 60 mA 1) |

| Output frequency for sine/cosine signals | ≤ 65 kHz |

| MTTF: mean time to dangerous failure | 210 years (EN ISO 13849) 2) |

- 1) Without load.

- 2) This product is a standard product and does not constitute a safety component as defined in the Machinery Directive. Calculation based on nominal load of components, average ambient temperature 60°C, frequency of use 8760 h/a. All electronic failures are considered hazardous. For more information, see document no. 8015532.

Mechanical data

| Shaft version | Tapered shaft |

| Flange type / stator coupling | Spring mounting plate, stator coupling |

| Dimensions | See dimensional drawing |

| Weight | ≤ 0.07 kg |

| Moment of inertia of the rotor | 4.5 gcm² |

| Operating speed | 9,000 min⁻¹, 9,000 U/min |

| Angular acceleration | ≤ 500,000 rad/s² |

| Operating torque | 0.2 Ncm |

| Start up torque | + 0.3 Ncm |

| Permissible movement of the drive element, static |

± 0.1 mm radial - 0.4 mm axial + 0.2 mm axial |

| Permissible movement of the drive element, dynamic |

± 0.05 mm radial ± 0.1 mm axial |

| Life of ball bearings | 3.6 x 109 revolutions |

Ambient data

| Operating temperature range | –20 °C ... +110 °C |

| Storage temperature range | –40 °C ... +125 °C, without package |

| Relative humidity/condensation | 90 %, Condensation not permitted |

| Resistance to shocks | 100 g, 6 ms, 6 ms (according to EN 60068-2-27) |

| Frequency range of resistance to vibrations | 50 g, 10 Hz ... 2,000 Hz (according to EN 60068-2-6) |

| EMC | According to EN 61000-6-2 and EN 61000-6-3 1) |

| Enclosure rating | IP50, with mating connector inserted and closed cover (according to IEC 60529) |

- 1) The EMC according to the standards quoted is achieved when the motor feedback system is mounted in an electrically conductive housing, which is connected to the central earthing point of the motor controller via a cable screen. The GND-(0 V) connection of the supply voltage is also grounded here. If other shielding concepts are used, users must perform their own tests.

Classifications

| ECl@ss 5.0 | 27270590 |

| ECl@ss 5.1.4 | 27270590 |

| ECl@ss 6.0 | 27270590 |

| ECl@ss 6.2 | 27270590 |

| ECl@ss 7.0 | 27270590 |

| ECl@ss 8.0 | 27270590 |

| ECl@ss 8.1 | 27270590 |

| ECl@ss 9.0 | 27270590 |

| ECl@ss 10.0 | 27273805 |

| ECl@ss 11.0 | 27273901 |

| ETIM 5.0 | EC001486 |

| ETIM 6.0 | EC001486 |

| ETIM 7.0 | EC001486 |

| ETIM 8.0 | EC001486 |

| UNSPSC 16.0901 | 41112113 |