Machinery Parts

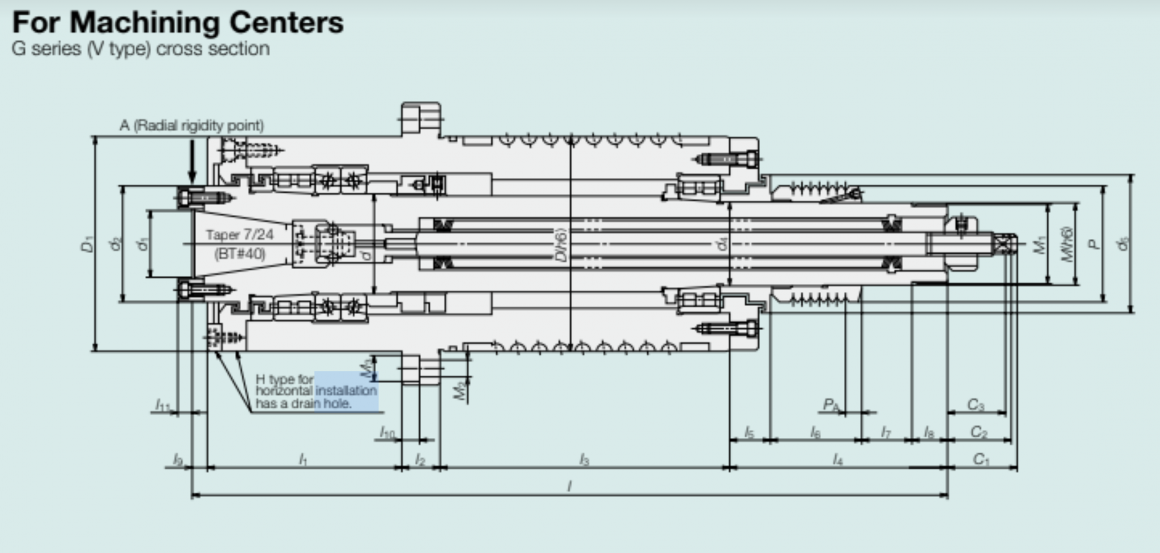

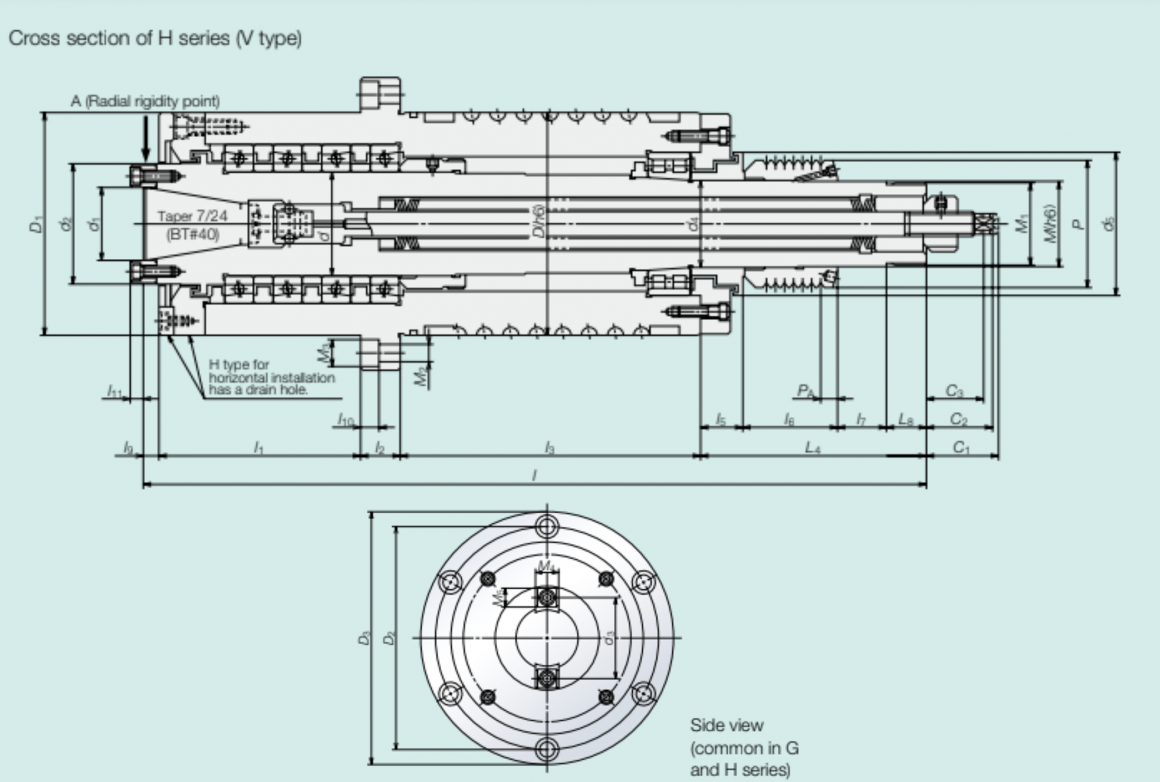

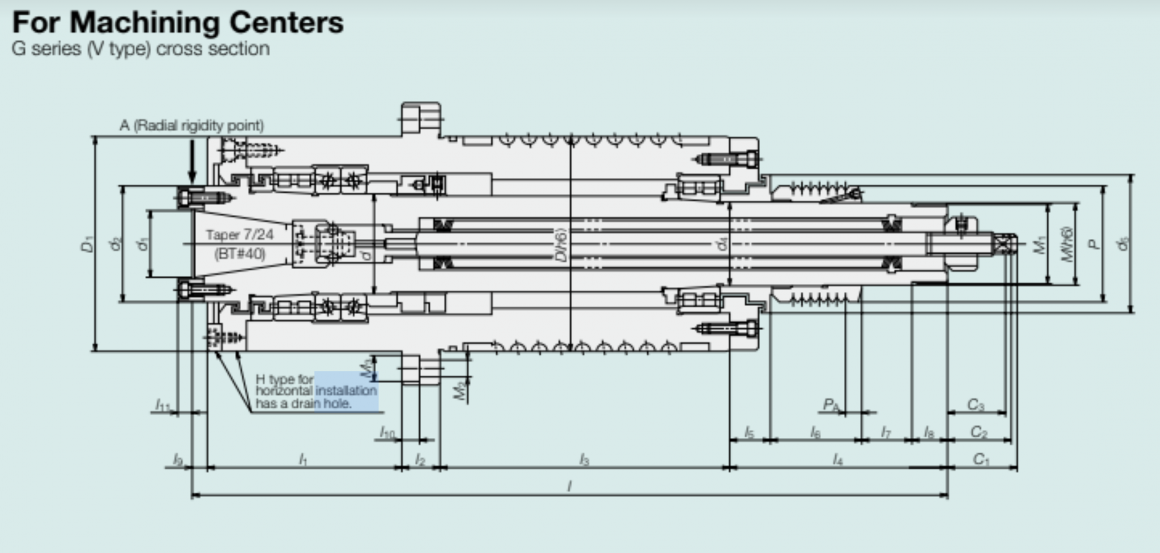

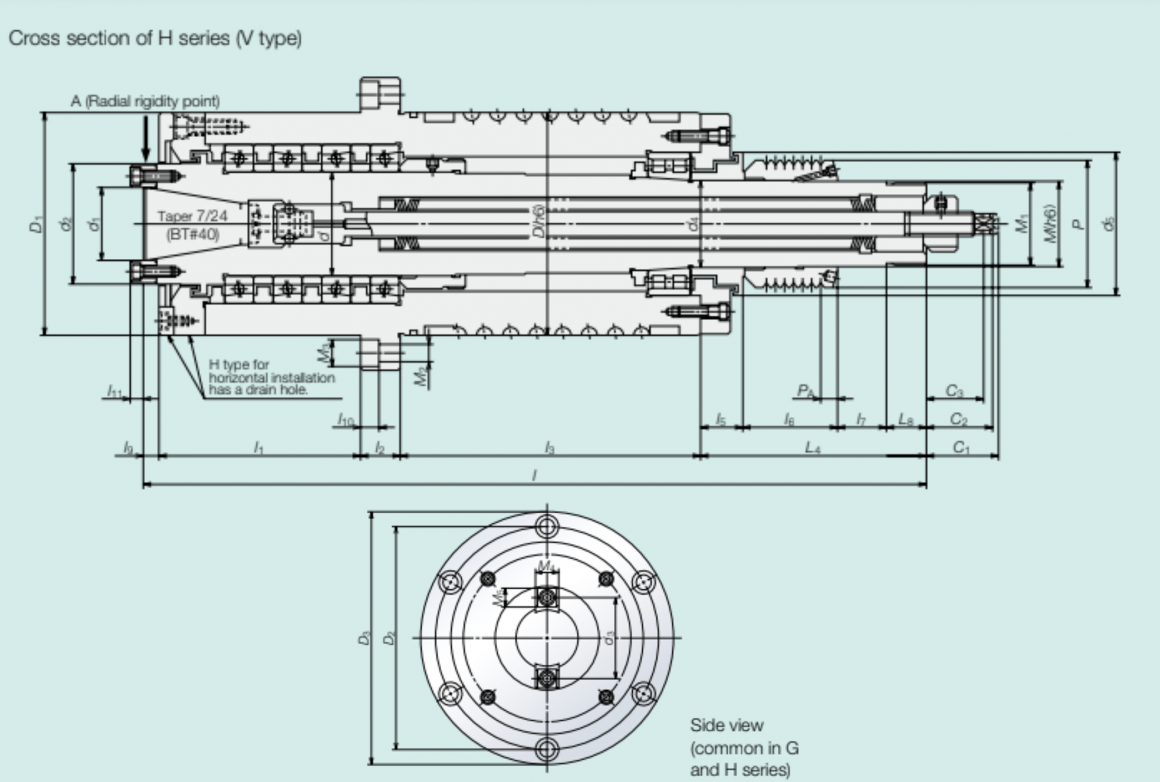

NSK Cartridge Spindle For Machining Centers

- G-40V(H)

- G-50V(H)

- H-30V(H)

- H-40V(H)

Types and Features

High-Rigidity G Series

High-Speed H Series

- High-rigidity G series (G-40V、 G-45V, G-50V)

- High-speed H series (H-30V, H-40V)

High-Rigidity G Series

Unit: mm

| National taper |

Max. rot. speed (min−1) | Runout accuracy (μm) max. | Average power consumption (kW) |

Pulley groove |

Rigidity (N/μm) (reference) |

Allowable static axial load (N) |

Spindle weight (approx.) (kg) |

Tool clamp force (N) |

Tool unclamp force (N) |

Tool clamp type |

|||||||||||||||

| Rev. speed | dm n max | Taper | Base of test | End of 300 test bar |

Axial | Radial (point A) |

|||||||||||||||||||

| G-40V (H) | 40 | 8000 | 62x104 | 2 | 3 | 8 | 5.5 | 5MS-7 | 275 | 245 | 25500 | 40 | 6870 | 8830 | Ball chuck | ||||||||||

| G-50V (H) | 50 | 4000 | 58x104 | 11 | 7MS-6 | 520 | 500 | 80400 | 140 | 14700 | 26500 | Collet chuck | |||||||||||||

Unit: mm

| Shaft dia. d |

NT Large d1 |

d2 | d3 | d4 | d5 | C1 | C2 | C3 | P | PA | D | D1 | D2 | D3 | M | M1 | M2 | M3 | M4 | M5 | l | l1 | I2 | l3 | l4 | l5 | l6 | l7 | l8 | l9 | l10 | l11 | |||||||||

| G-40V (H) | 65 | 44.5 | 76 | 60 | 55 | 90 | 44 | 40 | 35.4 | 76 | 10.5 | 140 | 140 | 162 | 185 | 50 | M50 × 1.5 | 11 | 17.5 | 15.9 | 14 | 480 | 124 | 24 | 184 | 138 | 27 | 57 | 31 | 23 | 19 | 11 | 8 | ||||||||

| G-50V (H) | 110 | 69.85 | 130 | 98 | 100 | 137 | 48 | 43 | 34 | 130 | 12.5 | 220 | 220 | 250 | 280 | 95 | M95 × 2.0 | 16 | 23 | 25.4 | 26 | 700 | 152 | 35 | 270 | 225 | 33 | 75 | 87 | 30 | 18 | 15.2 | 12.5 | ||||||||

High-Speed H Series

Unit: mm

| National taper |

Max. rot. speed (min−1) | Runout accuracy (μm) max. | Average power consumption (kW) |

Pulley groove |

Rigidity (N/μm) (reference) |

Allowable static axial load (N) |

Spindle weight (approx.) (kg) |

Tool clamp force (N) |

Tool unclamp force (N) |

Tool clamp type |

|||||||||||||||

| Rev. speed | dm n max | Taper | Base of test | End of 300 test bar |

Axial | Radial (point A) |

|||||||||||||||||||

| H-30V (H) | 30 | 12000 | 78x104 | 2 | 3 | 8 | 3.75 | 5MS-4 | 128 | 98 | 9800 | 28 | 3920 | 5100 | Ball chuck | ||||||||||

| H-40V (H) | 40 | 10000 | 82x104 | 5.5 | 5MS-7 | 167 | 137 | 12700 | 40 | 6870 | 8830 | Ball chuck | |||||||||||||

| Shaft dia. d |

NT Large d1 |

d2 | d3 | d4 | d5 | C1 | C2 | C3 | P | PA | D | D1 | D2 | D3 | M | M1 | M2 | M3 | M4 | M5 | l | l1 | I2 | l3 | l4 | l5 | l6 | l7 | l8 | l9 | l10 | l11 | |||||||||

| H-30V (H) | 50 | 31.75 | 57 | 44 | 45 | 74 | 34.5 | 32.5 | 27.5 | 64 | 11.5 | 120 | 120 | 140 | 160 | 43 | M42 × 1.5 | 9 | 14 | 15.9 | 11 | 390 | 111 | 20 | 146 | 106 | 25 | 41 | 22 | 18 | 7 | 8.6 | 8 | ||||||||

| H-40V (H) | 65 | 44.45 | 76 | 60 | 55 | 90 | 44 | 40 | 35.4 | 76 | 10.5 | 140 | 140 | 162 | 185 | 50 | M50 × 1.5 | 11 | 17.5 | 15.9 | 14 | 480 | 124 | 24 | 184 | 138 | 27 | 57 | 31 | 23 | 10 | 11 | 8 | ||||||||