Soldering

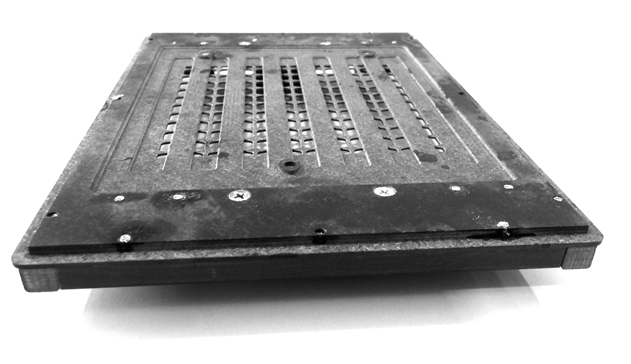

Wave Solder Pallet/Reflow Fixture

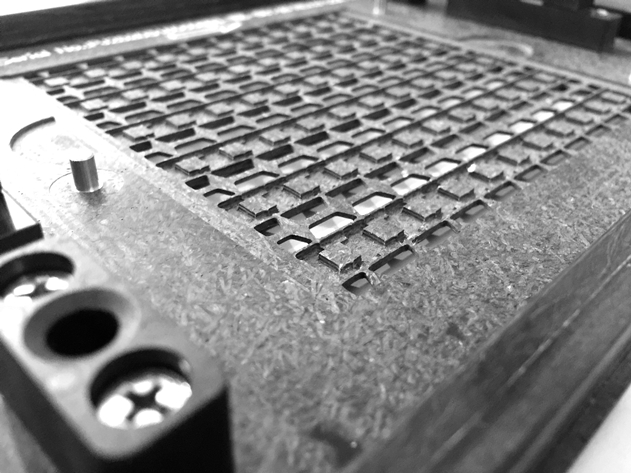

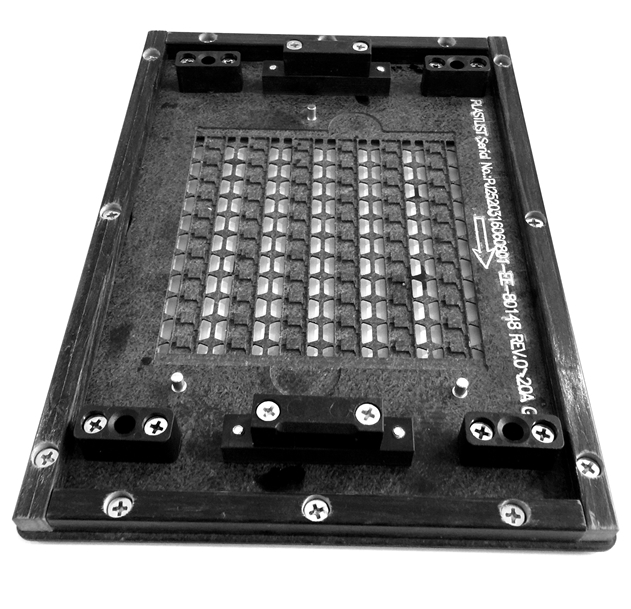

Wave solder pallets mask SMT components (ground planes, gold fingers and mounting holes)

while exposing the circuit board to the wave only where solder is required.

They provide thermal protection for printed circuit board areas that are heat sensitive.

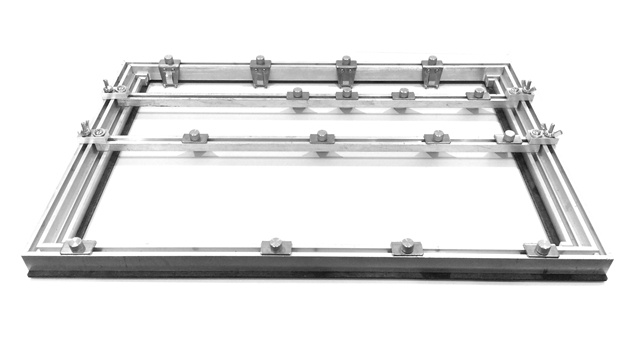

A wave solder fixture provides support for the PCB throughout the wave solder process.

while exposing the circuit board to the wave only where solder is required.

They provide thermal protection for printed circuit board areas that are heat sensitive.

A wave solder fixture provides support for the PCB throughout the wave solder process.

Plastlist wave solder pallets are lead to overall process efficiency by:

- Reducing set-up time

- Wave solder complex, double-sided circuit board assemblies

- Eliminating expensive, and labor-intensive masking

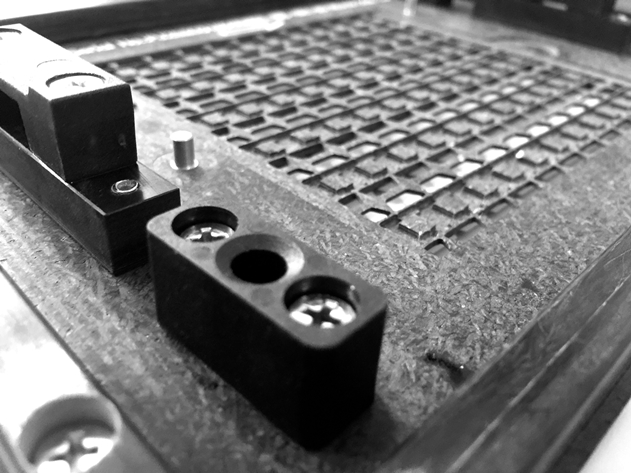

- Providing safe, easy, ergonomic handling of PCB

- Providing thermal protection for printed circuit board areas that are heat sensitive

- Processing multiple boards at the same time

- Reducing bridging and skipping solder defects

- Increasing production and enhance automated assembly

- Ensuring higher quality, repeatable process results

- High temperature resistance to endure repeated cycles through the reflow

- Dimensional stability to ensure board alignment is consistent

- Chemical resistance

- Very low moisture absorption

- Reduces solder defects

- Low heat absorption

- Reducing set-up time

- Wave solder complex, double-sided circuit board assemblies

- Eliminating expensive, and labor-intensive masking

- Providing safe, easy, ergonomic handling of PCB

- Providing thermal protection for printed circuit board areas that are heat sensitive

- Processing multiple boards at the same time

- Reducing bridging and skipping solder defects

- Increasing production and enhance automated assembly

- Ensuring higher quality, repeatable process results

- High temperature resistance to endure repeated cycles through the reflow

- Dimensional stability to ensure board alignment is consistent

- Chemical resistance

- Very low moisture absorption

- Reduces solder defects

- Low heat absorption